2

« on: 28 November 2007, 18:05:08 »

Hello,

I completed a Diff swap back in the summer.

Basically, take your time. Don't bother with ramps, as already stated, you need to rotate the wheels to get the driveshafts off. Here's a quick run down.

Jack the car up as high as you can and support the rear of the car on axle stands.

Soak the following in plus gas or WD40 at least 12 hours before attacking the job.

- The bolts holding the diff up, there are two at the rear and three on a mounting near the front.

- The pinion bolts

- The bolts at the wheel hubs

I personally left the exhaust in place will the last minute, so worry not about this for the moment.

Using some blocks of wood, wedge the wheel in turn as you remove the 6 bolts holding the driveshaft to the hub. You'll need a breaker bar, extension and a Torx to undo these. Keep these bolts, and the shims that come off (three in total) safe.

Once the shafts are loose, remove the bolts on the pinion, if I recall, the nuts come off but the bolts don't come out completely, keep the nuts safe. The prop should pop off with a little push, its best to tie it up or support it in an axle stand so it doesn't just dangle, as this puts additional strain on the centre bearing.

I managed to get one driveshaft out and had to leave the other one in, if I do the job again in the future, I'll use a crowbar to carefully prise it shaft out, I found it easier than wrestling a heavy diff complete with arm like driveshafts out from under the car!! Label each shaft left and right, so you know which ones which on refitting.

Lower the exhaust, possible even remove it from the cats back if you want it out the way completely.

At this point, I placed my jack at the rear of the diff (the heaviest part) and had a block of wood stretch out thus supporting the whole diff. I jacked up to take the weight and remove each large bolt, remembering where each came from.

Lowering the diff is interesting, I held and lowered very slowly guiding the diff down.

I pulled it out from under the car. Now is a good time to touch up any areas of rust with hammerite, perhaps even break out the waxoyl.

In an ideal world, we'd all have one of those massive three tonne jacks, with the big cup. This would allow us to mount the diff onto the cup and just jack it into position. In the real world, I used my 2.5 tonne halford jack and another jack, with a block of wood, effectively making a bridge for the diff to sit on. The diff was placed on and carefully wheels under the car. Ever so slowly, this platform was raised, till the rear of the diff was in position to get the bolts in at the rear, the two large ones. Lower the diff ever so slightly so it sits at an angle with the pinon facing downwards. At this point I placed the prop nearish the diff, slowly jacking up allowed the prop and pinion to mate together. You can now put in the three large bolts on the flexi mount, and tighten all bolts to the specified torque, USE NEW BOLTS FOR EACH OF THESE.

Now, I popped the driveshafts in and made sure that the circlip was present, I then check they should not be pulled out with a hard tug, and put all six bolts back in of both sides. Pinion nuts and bolts, all to torque values, using new bolts all round.

At this point, with the exhaust back on and everything together, but the car still in the air, I topped up the diff oil. With the car still in the air, I started her up and drove through the gears up to around an indicated 2500 RPM in 4th. This allowed me to listen for any undue noises from the diff.

A quick test drive revealed all was well.

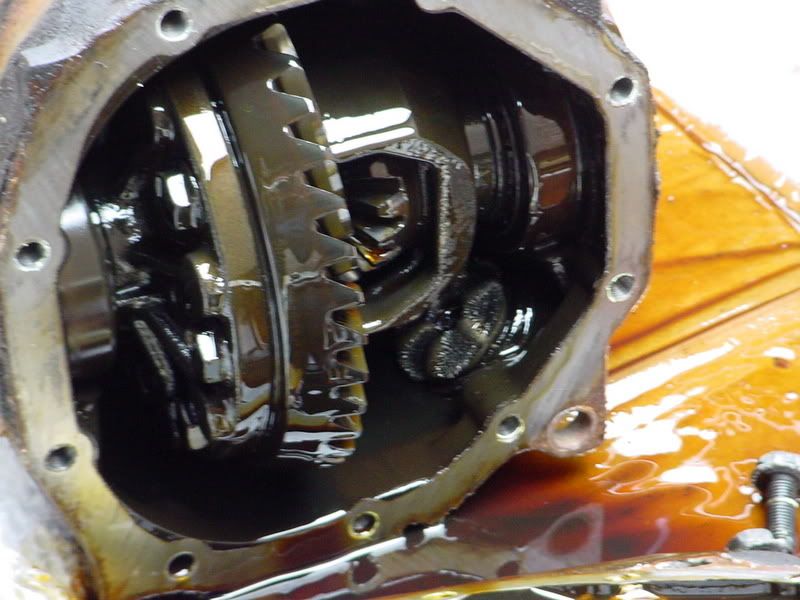

I can provide some photos of my experience if required.

James

, unfortunately, not being flushed with cash, I plumped for a second hand item with 28 day warranty

, unfortunately, not being flushed with cash, I plumped for a second hand item with 28 day warranty  .

.